PRODUCTS

Our production includes a wide range of hot-formed parts for various industries. Shapes and geometries vary considerably, with parts weighing between 30 grams and 15 kilograms.

This allows us to meet a wide range of requirements, from small precision parts to larger components.

Our most in-demand products include:

- NUTS

- FLANGES

- EYE BOLTS

- PLATES

- SHAKLES

- LEVERS

- CONNECTING ELEMENTS

- HOOKS

- KNIVES

- HUBS

- BEARING BUSHES

- FITTINGS

and other items based on customer drawings.

AREAS OF APPLICATION

We supply products for numerous technical applications in industry. We manufacture components for the following sectors:

passenger car and commercial vehicle industry, engine construction, trailer and container construction, lifting technology, gearboxes, earthmoving and mining, railway industry, hydraulics, fittings industry, agriculture, construction, mechanical engineering

Thanks to our experience and versatile production capabilities, we can respond precisely to the requirements of each customer, ensuring reliability, robustness and durability.

MATERIALS

We process a wide range of steels and alloys, which are selected according to the technical and functional requirements of the end product. The most frequently used include: carbon steel, high-strength alloy steels, stainless steel, titanium and special alloys on request.

Raw materials are labeled and stored with the utmost care. This approach enables us to work in highly critical areas where the technical properties of the components must meet strict parameters.

Carbon steels

Alloy steels

Stainless steels

Titanium

Special Alloys

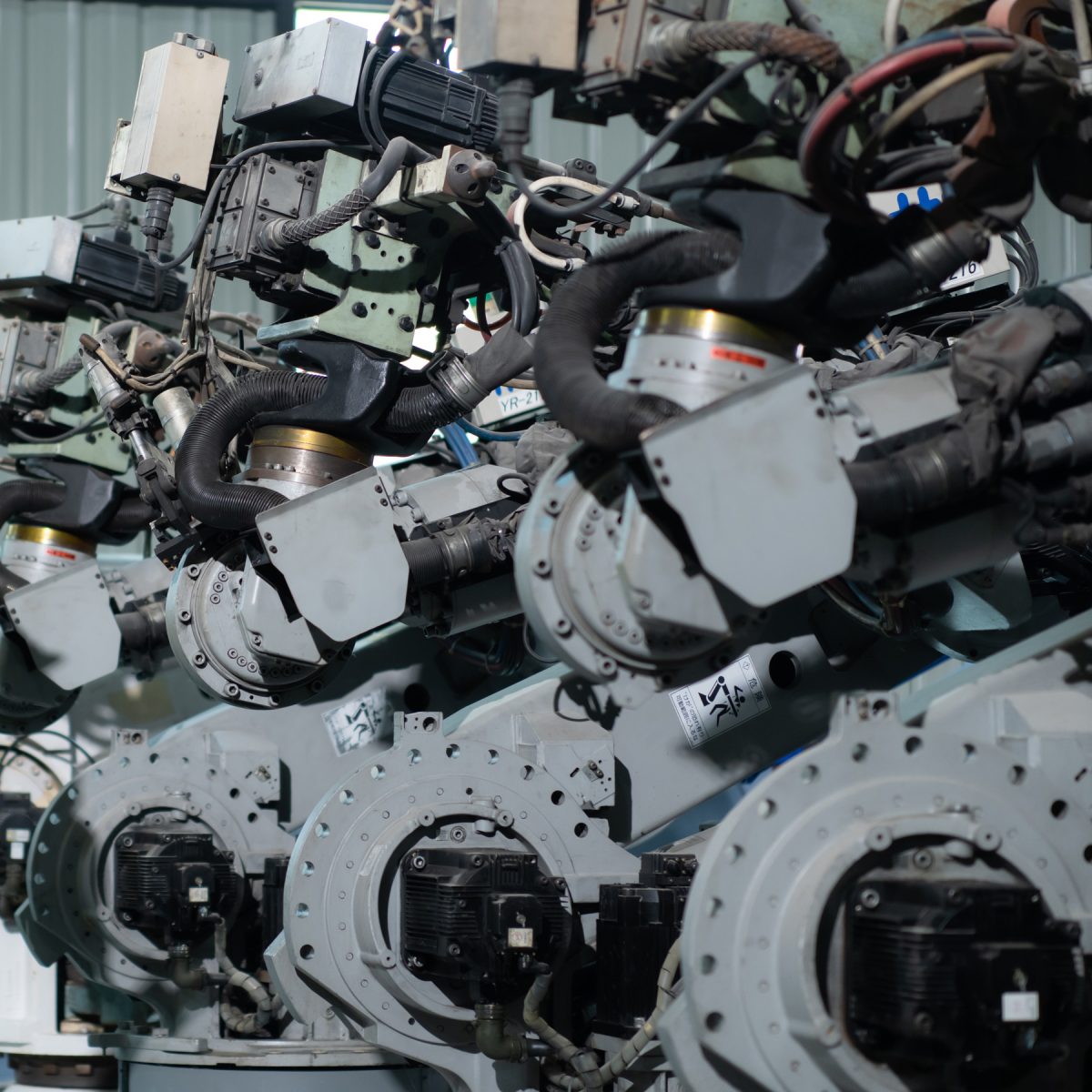

FACILITIES

Our factory is equipped with mechanical presses of various capacities, forging hammers and state-of-the-art induction furnaces. These systems enable us to process carbon steel, alloy steel and stainless steel, as well as special alloys and customer-specific materials with high precision and productivity.

All the dies and tools required for production are manufactured in-house based on technical drawings or samples provided by the customer. Our technical department is able to design and develop tailor-made solutions for any type of production requirement.

Valsecchi Roberto S.r.l.

Siamo a tua disposizione

Contattaci subito per qualsiasi informazione o richiesta